Typical mistakes to avoid when implementing an optical measurement system

Typical mistakes to avoid when implementing an optical measurement system

Blog Article

Why Optical Dimension Systems Are Essential for Modern Production Practices

In today's competitive manufacturing landscape, you can not afford to forget the benefits of optical dimension systems. These innovations enhance accuracy and speed in top quality control, decreasing human mistake that might lead to pricey problems. By incorporating advanced laser and imaging strategies, you'll improve procedures and improve product high quality. How specifically do these systems transform producing techniques, and what ramifications do they hold for the future?

The Advancement of Optical Measurement Solutions in Production

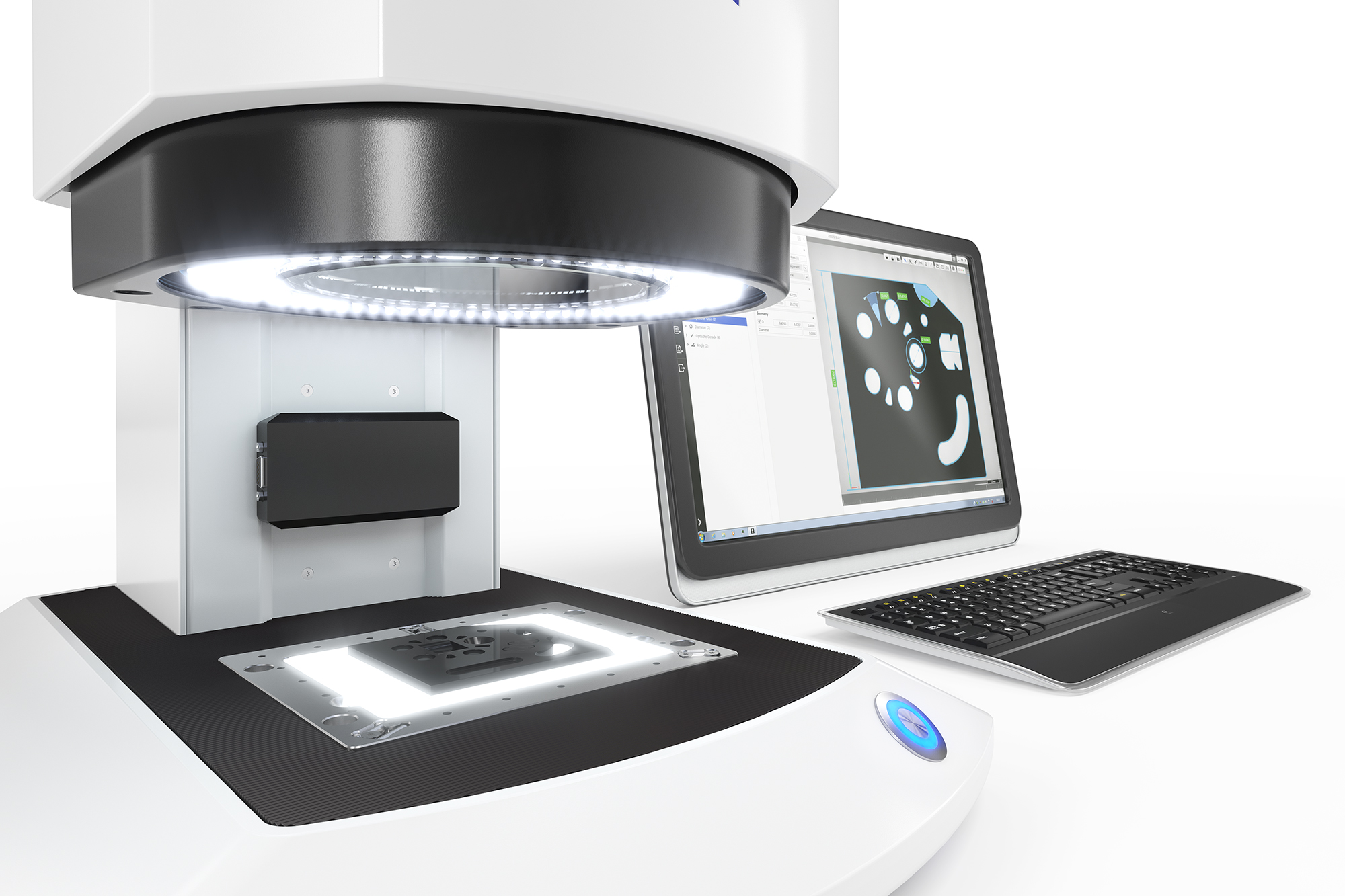

As technology quickly breakthroughs, the evolution of optical measurement systems in manufacturing has actually changed how industries ensure precision and top quality. You might've discovered that standard measurement strategies, like calipers and micrometers, often fall short in speed and precision. Optical systems become a remedy, leveraging light to capture comprehensive measurements quickly.

In the past, these systems were limited, mostly made use of for details applications. And now, developments in laser innovation and imaging software program permit functional, real-time analyses throughout numerous fields. When implementing these systems in your processes., you can expect higher precision and minimized human mistake. optical measurement system.

Furthermore, the integration of automated optical evaluation tools streamlines quality assurance, letting you concentrate on manufacturing efficiency. As the need for accuracy grows, adjusting to these ingenious optical measurement modern technologies will certainly maintain your operations reliable and affordable in a fast-paced market.

Trick Benefits of Optical Measurement Technologies

Optical measurement modern technologies provide several crucial advantages that can greatly enhance your manufacturing processes. They offer high accuracy and precision, allowing you to make important modifications with self-confidence. This causes improved item quality and minimized waste, which directly affects your profits.

Furthermore, these systems are non-contact, implying you can gauge delicate or moving parts without causing damages. This capability not just protects your products but likewise increases throughput considering that you can determine things on the assembly line without disturbance.

Optical systems are frequently quicker than traditional techniques, allowing you to collect data quickly and make prompt choices. Their flexibility indicates they can be applied to a wide variety of materials and geometries, adapting conveniently to your specific needs. By integrating optical dimension technologies, you're not just staying on par with sector standards; you're setting them.

Applications of Optical Measurement in Various Industries

While several markets are increasingly turning to advanced dimension methods, the applications of optical measurement systems stick out as a result of their unique capabilities. In automobile manufacturing, you'll discover these systems assisting to assure precise positioning and surface high quality in elements. In aerospace, they're necessary for evaluating intricate geometries and guaranteeing the security of critical parts.

In electronic devices, optical dimension aids in the exact positioning of integrated circuits on circuit boards, improving general performance. The clinical tool sector likewise benefits, as these systems permit the meticulous dimension of intricate components, ensuring they fulfill rigid regulative requirements.

Optical measurement systems are additionally utilized in textiles, where they examine material patterns and blemishes, boosting high quality. With their adaptability, these systems are changing just how different industries approach dimension, eventually driving innovation and performance in manufacturing procedures.

Enhancing High Quality Control Through Optical Dimension

When it pertains to quality control, accuracy measurement techniques can make all the distinction in your manufacturing process. By carrying out optical measurement systems, you can attain real-time quality control that keeps your products constant and dependable. This not only enhances your total production efficiency yet likewise boosts customer contentment.

Precision Dimension Methods

In today's competitive production landscape, carrying out accuracy measurement methods can significantly boost quality assurance processes. By utilizing sophisticated optical dimension systems, you can achieve greater precision and repeatability in your measurements. These strategies permit you to identify also the slightest variants in item dimensions, making sure that every part satisfies rigorous specifications.

Making use of tools like laser scanners and optical comparators, you can swiftly analyze the quality of your products, significantly lowering the risk of flaws. These systems give real-time information, enabling you to adjust processes instantly, thus minimizing waste.

Integrating these precision measurement methods not only enhances product high quality yet also increases customer complete satisfaction and confidence in your brand. Accept these developments to keep an affordable side in your production procedures.

Real-Time Quality Control

As producers endeavor for quality, real-time quality control comes to be necessary for maintaining high standards. Optical dimension systems play an important role in this procedure, enabling you to monitor item quality continuously. By incorporating these systems right into your operations, you can find discrepancies from specs almost promptly, minimizing the chances of issues reaching the marketplace. This immediate comments loop allows you to great post to read make fast modifications, enhancing production performance and reducing waste. You'll additionally promote a culture of high quality throughout your organization, as workers can see the straight impact of their job on end products. Inevitably, welcoming real-time quality control with optical dimension systems not only improves your output however also strengthens customer trust fund in your brand.

Lowering Waste and Improving Performance With Optical Systems

When you implement optical measurement systems, you'll see a considerable reduction in production errors. These systems improve quality assurance processes, making it much easier to determine and deal with concerns promptly. As an outcome, you not just minimize waste yet likewise improve general effectiveness in your production operations.

Minimizing Manufacturing Errors

To reduce manufacturing mistakes successfully, producers increasingly depend on optical measurement systems that enhance precision and minimize waste. These systems offer real-time feedback, allowing you to recognize disparities before they rise into pricey errors. By utilizing accurate dimensions, you can ensure that every component meets requirements, which significantly lowers the danger of defects. Additionally, optical systems can automate several processes, lowering human error and simplifying operations. You'll locate that implementing these modern technologies not only enhances productivity however also promotes a society of original site quality within your group. As you embrace optical dimension systems, you'll notice a marked decline in rework and scrap rates, eventually bring about much more effective production techniques and boosted bottom-line results.

Streamlining Quality Assurance

By taking on optical measurement systems, you're not only decreasing production mistakes but also enhancing high quality control. With precise dimensions, you can identify variants in processes or products promptly, decreasing waste and boosting general efficiency. Eventually, investing in optical measurement technology improves your top quality control, leading to much better items and pleased consumers.

Integrating Optical Dimension Systems Into Existing Processes

Next, choose the best optical measurement innovation that lines up with your production requirements. Think about aspects like the dimension of the parts, called for accuracy, and assimilation capacities with existing tools. Educating your personnel on the new innovation is vital; they website link require to really feel positive using it to maximize its benefits.

Finally, monitor the integration procedure very closely. Gather data on performance improvements and identify any obstacles beforehand. This positive method guarantees not only a smooth change however additionally a long lasting impact on your production performance and product quality.

The Future of Optical Dimension in Production

As you embrace optical dimension systems in your manufacturing processes, it is very important to look in advance and consider how these modern technologies will evolve. Future innovations guarantee enhanced precision and speed, enabling real-time responses that can considerably decrease manufacturing errors. You'll likely see the integration of expert system, enabling smarter data evaluation and anticipating maintenance. This indicates you'll not only determine but likewise anticipate problems prior to they occur.

In addition, miniaturization of optical sensors will certainly make them extra versatile, suitable right into tighter rooms and various applications. The increase of automation will certainly additionally enhance their abilities, as automated systems will certainly utilize these measurements to enhance production circulations seamlessly.

As you adapt to these modifications, remaining educated regarding arising modern technologies will be vital. By purchasing sophisticated optical dimension solutions, you'll position your manufacturing operations for long-term success and efficiency. Accept the future; it's brilliant for those that introduce!

Regularly Asked Inquiries

Just How Do Optical Dimension Equipments Contrast to Typical Dimension Approaches?

Optical dimension systems supply greater precision, effectiveness, and speed contrasted to standard techniques - optical measurement system. You'll discover they decrease human error and enhance information collection, making your dimensions a lot more reputable and enhancing general efficiency in your processes

What Are the First Expenses of Carrying Out Optical Measurement Systems?

You'll locate the preliminary costs of applying optical measurement systems can be substantial, usually entailing devices training, purchase, and software program. Nonetheless, these investments generally bring about higher efficiency and precision in the future.

Are There Specific Training Demands for Using Optical Measurement Equipments?

Yes, you'll need particular training to utilize optical dimension systems properly. Familiarizing on your own with the devices, software program, and measurement methods is important. Makers often supply training programs to guarantee you're qualified and certain in making use of these systems.

Can Optical Dimension Systems Be Customized for Special Production Needs?

Yes, you can customize optical measurement systems to satisfy your certain production demands. By adjusting parameters and integrating distinct functions, these systems can boost effectiveness, accuracy, and versatility, ensuring they line up completely with your manufacturing demands.

What Maintenance Is Required for Optical Measurement Systems?

You'll need to regularly clean the optics, adjust the system, and look for software updates. Monitoring efficiency and resolving any kind of wear or tear immediately ensures your optical measurement systems function properly and accurately with time.

Final thought

In today's hectic manufacturing world, welcoming optical dimension systems is important for staying affordable. These innovations not only improve precision and rate however also boost high quality control and decrease waste. By integrating these innovative options into your procedures, you'll cultivate a culture of integrity and client complete satisfaction. As you look to the future, purchasing optical measurement will certainly ensure your operations continue to be efficient and compliant, placing your company for ongoing success in the ever-evolving landscape.

As modern technology quickly advances, the development of optical dimension systems in manufacturing has actually changed how sectors guarantee precision and top quality.While numerous sectors are increasingly turning to innovative measurement methods, the applications of optical dimension systems stand out due to their unique abilities. By making use of advanced optical measurement systems, you can accomplish higher accuracy and repeatability in your measurements. Optical dimension systems play an essential role in this process, permitting you to check product high quality constantly. Just How Do Optical Measurement Solutions Contrast to Typical Dimension Methods?

Report this page